November 12, 2023

And another seven years later

Time flies. It really does. Late 2023 now, and the RSX is still with me. It's sitting in the garage, shinier than it has in many years, thanks to a comprehensive detail job I treated the car to. I've had the car for 20 years now, got it new at Elk Grove Acura in November 2003 when I still lived in California. It has 28,350 original miles on it. And it's amazing how practically new a 20 year old car can look when it is always garaged.

The world has changed so much since I got the RSX. Back then, if you wanted real bolt-on power it was the usual intake/header/catback combos, which didn't really bring much, or it was the Jackson supercharger. The Hondata reflash added some nice midrange power by optimizing things and lowering the VTEC point so you switched to the high cam sooner. Then Hondata launched the KPro and Comptech entered the RSX supercharger business and things began taking off. Turbo barely was an option back then, with just a few 6psi Greddys around.

Back then, few of us RSX guys actually "built" a car with cams and pistons and blueprinting and balancing and all. With the Comptech supercharger, CAI, KPro and a few other Comptech goodies, my 04 Type S eventually got up to 290 whp on Driving Ambition's conservative dyno, so roughly 340 at the crank.

I used to love taking the RSX to the Wednesday drags at Sacramento Raceway. Lots of fun, some great memories, and a nice collection of trophies, including one "King of the Track" trophy where I came out on top of all classes in bracket racing. Then I moved to East Tennessee where there are only 1/8th mile tracks, which I hate because with our FWD cars' lack of traction (even with a Quaife), the race is over before before I get full traction.

And now it's a totally different era, what with ludicrously fast Teslas and other electrics, and, thanks to turbo, horsepower way up across the board. Turbo changed everything. I chuckle when I read a young kid saying on one of the RSX groups I belong to that he just wants "a small power boost, maybe 400-500". And apparently that is possible today. It would have scared the hell out of me back then. Heck, I still sometimes worry when I floor my RSX and hear that wonderful supercharger whine as the motor rushes up to almost 9000 rpm for the shift. I worry, even though my car was done by Comptech, very professionally.

But it's 20 years old now. Just five more years and it qualifies as a "classic." It looks like new, but it's 20 years old. It has ridiculously few miles on it, but I really need to change all the fluids, all of them. The synthetic oil, of course, I've changed very regularly.

I've kept a list and log of all of my mods. Most were done in the car's first couple of years. There's only been three entries since 2005.

One was upgrading my very early Hondata KPro up to version 4. That was a bit of a mixed blessing because the daughterboard was ill-fitting and had loose screws, and thanks to much stricter regulations there are now some hoops to jump through before the KPro activates. Honestly, I have barely spent any time with all the new capabilities. KManager still looks pretty ancient, but it has so many new features that I just haven't had the time to get into it.

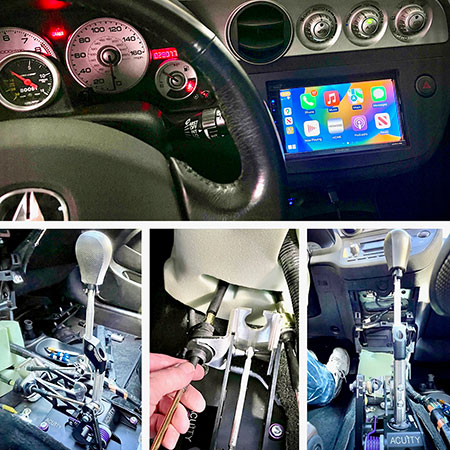

Another was that I exchanged the OEM factory radio/CD changer with a Kenwood DNR476S head unit with touch screen, GPS navigation and Apple Car Play. I got that from Crutchfield, with all the proper adapters and cabling, and it wasn't a real big deal to put it in. It's one of those things that is a headache to do the first time, but a second time it'd take just a few minutes (not that I expect a second time). The Kenwood looks and works fine, but it's slow to boot and the tiny buttons are hard to read and operate. If I had to do it over, I'd go with a higher end unit and install all the other stuff the unit can do, like multiple cameras and such.

Finally, I put in an Acuity 4-way adjustable performance shifter. The Acuity is costly, but oh so nice. This was my third shifter replacement. First I went from stock to B&M (which had an inherent flaw in it), from B&M to Comptech (which was a bit of a work in progress), and now Comptech to Acuity). I love the Acuity! It is infinitely adjustable and feels much more precise.

Next I'll replace the replace my (too-harsh) suspension setup with its lowered stock springs with a set of front and rear strut & spring assemblies from TRQ. I had looked at various coil-overs, but decided on the TRQs that look almost exactly like the Mugen Sport Suspension that I had years ago, with a 1.5-inch drop. And I'll replace the idle valve to hopefully cure the often somewhat unsteady idle of the car.

Will I keep the RSX forever? Who knows. It's in such great shape, drives so well, and has such low miles that I'd hate to let it go. And with new car prices so very sky-high and RSX prices just slowly going up, it'd almost be stupid to sell it and getting little in return.

Posted by conradb212 at 7:49 PM

February 2, 2016

Eight years later

It's early 2016 now, and the RSX is still with me. And with me means I had the car shipped from California to our new home in Tennessee, where we've been living since June 2015.

So now the RSX, which still only has 25,000 miles on it, gets to sip 93 octane fuel instead of the miserable 91 octane California brew. No more ugly front license plate either, and no more having to deal with sadistic smog Nazis. Unfortunately, also no local 1/4 mile track. The closest of those, I am told, is near Nashville. Around her, with all the available land, all there is is a 1/8 mile track. I hate those. By the time the car gets traction, the race is already over.

Only 25,000 miles, but that doesn't mean the car's just been sitting. I haven't been racing either. That's mostly because back in 2008 the car got stranded at Sacramento Raceway when the alternator, which shares the blower serpentine belt, got ripped right off its base when the tensioner base shattered during a burn-out. That was embarrassing, as was getting towed back home. So that was that for drag racing at the track.

The tensioner was replaced with the latest version and I throttled power back a bit by switching to the less aggressive 3.2-inch (I think) 8-psi pulley. For the next several years I just took the car out for fun, enjoying the thrilling supercharger whine.

In 2010 the car had to get smogged for the first time. That's what you need to do at the 7th anniversary of initial registration. The car passed smog with flying color, producing only a small fraction of allowable emissions, but the smog place wouldn't pass the car because they didn't like a hose that came with my CARB-approved cold air intake, and they claimed my street header sticker was only good for model years 2002 and 2003, but not for 2004, which my car is. Never mind that 2002-2004 cars are identical and that the header was good and approved for all of those cars. No, I had to get a sticker that specifically said 2004 as well. All in all, I had to go back to the smog place three extra times.

Obviously I didn't go back to that smog station that seemed to get sadistic pleasure about not passing modified cars. The place I went to in 2012 was more reasonable, but they objected to the cold air intake sticker only being for 2002/2003, but not 2004... So I had to contact AEM, submit an extremely detailed form with all sorts of information to get a sticker that said, oh, yes, it's the same exact intake for 2004.

No smog issues in 2014.

Around that time I noticed the car thumping over pot holes much more than before. I spent hours checking for something loose, as that's what it sounded like. Didn't find anything, and so brought the car back to Shad at Driving Ambition. Turns out one of the Mugen SS rear shocks was totally shot. That was rather a disappointment, as I didn't expect a Mugen shock to go bad after no more than a very few thousand miles. So I had Shad ditch the entire Mugen setup and instead install a set of lowered stock coils that had once been in Howard's RSX test car (Howard had worked at Comptech with Shad). And while Shad had the car, I had him put the 3.0-inch 9-psi pulley back in. Oh, and I also had him take out the rock-hard Enjo motor mounts and put the stock mounts back in.

The result was mixed. The lowered coils make the car much harder, and somehow they rattle in the front. Not happy about that. And so far I haven't even updatd the tune for the more aggressive pulley (or the 93 octane Tennessee gas).

Another thing I did was get a set of new Goodyear G-Force Rival tires. I did that not because the existing rubber was all gone, but in the rear I still have the original slippery stock Kumhos, and the Falken Azeni 615s in the front were a bit worn and definitely getting hard. So after a good deal of research I got the Riva;s, which are very sticky but have a very low wear rating to go with that. No problem, I don't drive the car much. The Rivals definitely have MUCH better grip. Hey, no more wheel spin in 3rd gear.

So today I had the oil changed. The existing Mobile One fill probably had no more than 2,000 miles on it, but it was several years old, and I won't take any chances with oil. The oil change at the Honest One Auto Care place off Kingston Pike was quite expensive, but they folks there were terrific. And they loved the RSX. Talked to Joe at length who has a heavily modified Accord (not many heavily modified Accords out there, I think). And another one of the guys actually thanked me for letting him work on my car. That was very nice.

So who knows. Perhaps my supercharged RSX hasn't seen its last modification yet, nor perhaps reached its peak power...

Posted by conradb212 at 10:36 PM

December 5, 2007

Supercharger weak spot: the belt

There's nothing like taking a car with a clean bill of health to the track, and so the supercharged RSX has seen some duty as of late. After the dog-days of summer with Sacramento temperatures in the triple-figures, going racing in cooler October and November nights was pleasant indeed, and I hoped it would bring good 1/4-mile times, which it did, to a degree.

As I often do, I brought along my notebook computer and datalogged my runs to see if there was detonation and whether the car ran rich or lean. I've long since given up my earlier quest (obsession, really) to get an absolutely flat, perfect air-fuel ratio at all revs as it is simply not possible. Get it just right, and a week later it's all out of whack again for one reason or another. Temperature, datalogging conditions, maybe even different gas. Who knows. So now I primarily concentrate on the bigger picture: make sure fuel is approximately right without any big peaks or valleys, and make sure there is no detonation.

One cool October evening the car ran quite well, knocking off 13.6 time trial runs on my street tires, and I hoped for even better once it got cooler yet (and perhaps with, finally, The Perfect Launch). Alas, just before eliminations began I opened the hood when someone asked to see the Comptech supercharger and what do I see but another almost shredded belt! With the new tensioner that was supposed to fix everything. I called it a night and babied the car home.

A consultation with Shad and Ryan at Driving Ambition revealed that the belt had apparently stretched enough to max out the tensioner's internal adjustment, and so all it took was one little belt hop to shred a couple of grooves. A new, shorter belt went on and Ryan explained to me how to adjust the tensioner.

Back to the track. The car, again, ran great, doing 13.6 and 13.5 runs, but my launches were miserable and so I lost in early rounds each time, not being able to really see what the engine with its belt totally tight at last could do. With the old tensioner I never saw more than 8.2 psi of boost. With the new one that is now up to 9.5 and sometimes 10psi, and the car feels very strong.

Posted by conradb212 at 3:36 PM

August 17, 2007

Highs and lows

I think every hobby has its highs and lows. The highs are when you are really into it. You're dealing with your hobby -- in this case your tuned car -- almost every day and you're involved to the max. The lows are when the interest sort of gets sidetracked or goes away, maybe just for a time, maybe forever. There was a time when I posted at ClubRSX every day and knew just about everything that went on. Then a time when interest sort of went away. I wrote about that in my last post, more than a year ago.

So an update is overdue. After that big win in October of 2006 I was determined to go back to the track and finally run consistent low 13s. In fact, the very next week, late in October of 2006, I put my Hoosiers in the trunk and headed for Sacramento Raceway. Jacked up the car to replaced my street wheels with the Hoosier wheels but, alas, I had forgotten the special key for the locked lugnut that keeps fancy wheels from being stolen. So no Hoosiers. Worse, once racing began I seemed to have forgotten how to shift. I missed third twice, and then, actually managed to shift from second back into first. The engine, of course, howled in protest and things could have gone really bad in a hurry. Fortunately, I instantly jumped on the clutch and so the transmission wasn't blown. Still, I coasted the rest of the way and then did just one other run, scoring a miserable 14.3.

Had I done something to the engine? K-Manager did find an "Engine Over-rev" code. Not good. The car seemed to run fine, but I didn't trust it again. I stopped by Comptech in El Dorado Hills for something, and asked if we could do a leakdown test to see if a valve was bent. That had to be postponed. Ryan told me a new tensioner was about ready and I should stop by the first week of 2007. I forgot.

What happened next was sad. I went back to Comptech in March or so, just to find that the company was in the process of being dismantled. Shad Huntley had left to start his own shop, Driving Ambition, in Gold River, California. Almost everyone else was gone. There were no tensioners.

So my 2004 RSX Type S just sat. I didn't want to race it not knowing if something was wrong with a valve. Eventually I learned that Comptech sort of lived on. The machinery was sold to one company, and one of the Comptech sales staff took over most of the aftermarket inventory and started a new Comptech shop in Rancho Cordova.

I contacted Shad at Driving Ambition to see if he had one of the new tensioners for my supercharger. He had one, but that was spoken for. And that is how things remained for several months. So my car sat in the garage. Then Shad called and said he now had a tensioner. We set up an appointment, the new tensioner was installed and a compression test gave the car a clean bill of health. Yeah!

I went to the track that very day, in the high heat of the summer, and had one of those nights where I was in a zone. My reaction times were on the button every time. No mis-shifts, no wheel spin, everything went perfect. Even my opponents cooperated by either sleeping through their lights or grossly misjudging their dial times, or both. I ran 11 races that night, and ended up braking before I crossed the finish line 10 times. It was boiling hot and I did not want to wear my helmet, so I dialed a 14.0, the cut-off for needing to wear the helmet. Attendance wasn't great due to the heat and so the eliminations proceeded quickly. By 9PM we were done and so the organizers decided to do a "King of the Track" shootout. As the winner of one of the two import categories I raced the other import winner, a Nissan 350Z, and won. The final race was between me and the domestics winner, a Corvette that ran low 12s and had entertained the crowd with fierce burnouts the whole evening. Well, he slept while I nailed another launch, and easily won. The RSX was back, and I had won "King of the Track."

Posted by conradb212 at 2:45 PM

October 15, 2006

Back at the track -- and winning!

It's been a long while since my last entry, and almost as long since I had my car on the road. A few things transpired to make me sort of fall out of love with the car and the entire racing and tuning scene. No one thing is responsible; it was just a whole bunch of little matters that all piled up until it was enough for me to just park the car in the garage.

First, when tuning and racing and modifying, you need a support group. In my case, I was lucky to have this awesome interenet community in clubrsx.com, two supreme tuner shops in Hondata and Comptech, and then all my friends online and at that track. Yet, things can happen.

I had been involved in ClubRSX, one of the most active automotive enthusiast sites on the planet, since last 2003, just after I had bought my new Acura RSX. Over the next two years I posted well over 4,000 messages, most quite long and meaningful. I wrote FAQs (Frequently Asked Questions with explanations and answers) for the ECU forum and the supercharger forum, and became a moderator in those forums. I set up my own little website where I described and chronicled my expriences. I also helped hundreds of people via email with tuning their cars. All I really needed were a few datalogs per my specifications, and I could immediately see what was right and what was wrong, and fix it.

My involvement seemed to approach a new high when ClubRSX owner Chris Dye approached me with the idea of becoming Editor-in-Chief of Club RSX. I had long played with the idea of doing a ECU Tuner magazine, and had also felt ClubRSX was a bit lacking in tech articles and a generally attractive look and feel (beyond the awesome forums). So the thought of revamping the site, adding magazine-style features, interviews, reports, and so on, and giving it a cool look, was appealing. After some back and forth I called Chris Dye to discuss it all. It was a good, long talk, but I also learned that Chris wanted me to do this for free because he had been burned in the past with paid contributors/staff. I could see that, but also felt I was in a different class from the people who might have burned him. I am a professional writer and publisher with many years of experience under my belt. I certainly never rip anyone off. In addition, with print magazines going by the wayside, my business cannot afford to do free work to any meaningful extent. So as much as I would have loved to take a very active role in revamping ClubRSX, I could not do it for free.

A second component was that I didn't feel the support I felt I needed from my two favorite tuner shops. Comptech USA is ten miles from where I live, and they have certainly been a pleasure to work with. I was their test pilot for the RSX supercharger. It was a long, long process, but I eventually did end up with the first supercharged RSX in customer hands. While I did pay for it all, they gave me generous terms, and often gave me, or installed, parts to test, or just because they did not need them anymore. I repaid them by offering my almost new car as a test platform, by datalogging and modifying the ECU calibration until it was just right (and found its way into the final customer product), by testing new and experimental parts, and by letting them have my car for extended dyno testing. I bought a heavy duty clutch/flywheel/pressure plate from them and paid full rates to have it all installed. In return, I was promised I'd get the first aftercooler for free.

Sadly, the aftercooler never happened. The parts are still sitting at Comptech. And Shad Huntley, my primary contact at Comptech, left the company to start his own shop. With him gone, I no longer have an easily reachable contact at Comptech.

Hondata, meanwhile, was a great source of inspiration but occasionally also one of a bit of frustration. They have an absolutely awesome product with their K-Pro ECU and accompanying software, and the two principals are as dedicated and competent as it gets. Yet, I had hoped to eventually have a closer relationship. I felt that I was both a champion for them, probably being responsible for selling numerous K-Pros via my very extensive reporting on K-Pro and its software, as well as tech support via answering numerous questions and helping with debugging and so on. I also provided beta-testing to Hondata, asked questions and made suggestions that all improved the product. I even created a temperature compensation calculator that was later incorporated into the software. While I had some very good interaction with the principals, and while I was actually invited down to Hondata to spend a very instructive day of training, I also felt a bit frustrated by the small amount of true interaction. I felt I could have helped them a lot more. Maybe I was too sensitive, but I still feel it was a lost opportunity, and so much more could have been done.

Next, after Shad left Comptech, my car also began letting me down. Nothing major. One time, after a single track session with a few burnouts, I noticed an almost ruined belt -- the bain of all supercharger drivers. That was replaced and the tensioner adjusted. Yet, after my next outing at the track, where the car ran poorly, the belt once again showed signs of deterioration. One of the ribs was nearly broken off. And then I had a "Check Engine" light.

It so happened that around the time that happened I discovered a new sport that quickly became a passion: scuba diving. I joined an online community, made friends, and before I knew it enrolled in an Open Water Scuba class. That was pretty intense and I enjoyed it tremendously. I studied hard, eventually passed my certification dives, then bought a whole set of scuba gera and set up a scuba website. And even did high altitude diving. If you have never done it, floating weightlessly underwater is incredible. Addictive. Unique. Try it.

But there was no way I could overlook that shiny black RSX in my garage every day as I got into my turbo PT Cruiser to go to work and come back home. I raced the Cruiser and ran mid-14s, having lots of fun. But everytime I went to Sac Raceway, people'd ask me, "Hey man, where's your RSX?"

So eventually I did what I had meant to do. I took out the plugs (you need one of those extra tools to get the little suckers out) and found them okay (at least according to Autozone; Kragen declared them "fried") but with an unusually large gap of at least 0.45! I looked up what the folks at ClubRSX recommended and regapped them to 0.30. Then I replaced the 510cc Power Enterprise injectors with the Comptech-modified Honda injectors. I updated my K-Manager software and uploaded it into my ECU. The car ran fine, albeit rough thanks to the Enjo motormounts I had Comptech put in. That was a decision I still sort of regret, though in time I may feel differently.

On October 11, 2006, I took the RSX to the track again. I datalogged the first two time trials to see if I had knock and if the Air/Fuel ratio was okay. No knock. The AF was too high in the first run and so I added 5% fuel from 6000rpm on up on the 50 degree cam. The second run was fine. Despite wheelspin I managed a 13.9 and a 13.8. Better than during the dismal outing before the hiatus.

As the evening wore on, the car ran better and better. I got lucky in one trophy run as my opponent, a guy who had stuffed a K24 into an old Integra, misshifted and I blew by him at the very end. In one run I ran a modified Dodge SRT-4 heads-up and was so far ahead that I got off the gas early and coasted through the line with a 13.74 on a 13.7 dial. That was too close for comfort and so I lowered my dial to 13.6. In the finals I faced another Honda and had a huge 2.3 second handicap. He caught a perfect 0.004 second light to my mediocre 0.25, and so I barrelled after him after, again, a bunch of wheelspin and a much less than optimal launch. The RSX ran like a demon, though, and I caught him at the finish line, but wasn't sure if it had been in time. Yes! The "win" light lit on my side.

I found that my opponent had broken out whereas I had run a 13.602 on my 13.600 dial. Another trophy. I was quite happy. Then, on my way home, another "check engine" light. In my garage I hooked up the computer and diagnosed it as a P0505, "Idle Valve Malfunction." No fun. I read up on it and it'll be a job to get to it and clean it, in the hope that it may be fixable.

Posted by conradb212 at 2:08 PM

February 17, 2006

ECU Tuning - Too much information?

So I get early to the racetrack in my supercharged 2004 Acura RSX and end up the first car in Lane 6, waiting for the time trials to begin. Usually they do it by lane, but this time they did it across lanes. It was a cold day, and so my car wasn't really warmed up when I was suddenly told to stage for my first run.

I got off to a good start, but the car felt sluggish. There just wasn't any power even though the boost gauge blinked at me, signaling I had exceeded the 10 psi boost limit it is set for. The time slip said it all: a 15.2 second quarter mile at 93 miles per hour. That's a second and a half slower than usual.

Fortunatly, I had datalogged the run on my laptop, connected via USB to my Hondata K-Pro ECU. The log showed that I had run very high boost, up to almost 11 psi as opposed to my normal 8 psi or so. I had also shifted at 7,500rpm instead of the usual 8,600. That's because the engine just hadn't seemed to want to rev any higher. Air-fuel ratio seemed fine, though on the rich side at about 11.5. I had almost 40 knocks, which seemed very unusual as my car is tuned conservatively. So I looked for anything else that might have been wrong, and finally I found it: the Honda K20a engine had never gone into VTEC. I had run the entire race on the low cam.

What should happen is that under full throttle, the ECU issues a signal that then switches the VTEC solenoid, oil activates a switch, and the cam mechnism changes to the high speed cam, commonly known as the "VTEC" point. Mine didn't. There was no VTEC signal at all. So I pulled out of the lane and parked the car as I didn't want to risk damage. I then datalogged and found that gunning the engine still did not produce a VTEC signal. I checked the oil, which I had changed that same morning, to see if perhaps I was low. I wasn't. I also didn't see any physical damage that might have been done by the service station. I then checked a datalog from earlier in the day, and there was a VTEC signal.

I then reloaded the calibration into the ECU, thinking something may have been off with it. No dice. Since I use an older version of the Hondata K-Manager software, I decided to load the latest version and then upload the calibration again. Nada. I called Comptech in the hope that someone might still be there and may have a clue. No one answered. I asked a guy who also has a Comptech supercharger and who works at an Acura dealership. Everything looked fine to him.

Then I notice that the latest version of K-Manager lets you set the speed below which VTEC will not kick in. It is 6mph. So gunning the engine while parked would not have triggered the signal. I changed the setting to zero mph and upload again. Bingo! We have a VTEC signal. So I decide to race again (I did poorly).

I still don't know why there had been no signal and begin to suspect that it may have to do with engine temperature. I send an email to Derek at Hondata and he answers right away. Yes, VTEC needs an engine coolant temperature of 140F whereas my car had been at 136 degrees. Case solved. And no, he doesn't think revving that high on the low cam did any damage, an assertion later repeated by Comptech technicians.

Sooo... having the latest and greatest in ECU tuning and datalogging tools had allowed me to figure out what ailed my car. It didn't give me an immediate answer as the 140 degree cutoff wasn't documented anywhere. Without datalogging I wouldn't have known what was wrong and likely just would have tried again. The car would have been hot and VTEC would have been normal. Does that mean our new ECU tuning tools make us too reluctant, too scared of every variable that seems a bit off?

Posted by conradb212 at 2:07 PM

January 22, 2006

My first NHRA point racing experience

I didn't really WANT to enter NHRA point racing, but somehow I ended up in it. All I wanted was try out the Hoosier drag radials I had bought from OsideJimC. Sadly, even in mild-weathered Sacramento, California the Wednesday fun drags don't start til February, and I could not wait that long. So I became part of Team Sacramento. Car number, T-shirt and all.

Those who are familiar with Sac Raceway know that its website, representing web page technology of circa 1997, is cryptic to the max and rather devoid of information such as start times or anything that could help a noob. However, Jennifer there promptly answered my email and so I motored on over this Sunday morning. It was so foggy I couldn't see a thing when I left my house, but by the time I got to the track is was a cold, sunny morning.

Everything, of course, was completely different from the Wednesday fun drags and so I felt like a first grader on his first day at school. Get a wristband to get in, but to actually register for racing, that'd be at the souvenir stand. There's a long line there and I notice something else: whereas I am usually among the oldest at the Wednesday fun drags, here I am actually one of the younger guys. And whereas the fun drags are usually about 50/50 imports and domestics, this is almost 100% big, hulking Detroit iron.

So I try to act cool while still asking a bunch of questions to get the basics: Do you need to drive the same car all season in points racing? (No). Can you switch classes during the season? (Yes). Where do you change your wheels? (Anywhere). Should you secure them? (Naah. No one steals anything). Where is tech inspection? (Oh, in the pits. Somewhere.). How do you know which lane to go in? (The loudspeaker will call your class and tell you.) Oh good. The registration lady is both helpful and hot (how often are those two qualities combined in one person?) and so I am on my way.

I park somewhere and change my front wheels. No big deal, but on an ice-cold morning not much fun either. But hey, that's just the way it is. Even though I was told no one steals anything, I secure my nice front wheels to the grandstand structure with a nifty locking mechanism I had picked up at Walmart. I mean, someone stole a notebook computer out of my car IN MY GARAGE.

No one shows up for the tech inspection, so I drive over to the lanes and have it done there. "Sportsman time trials in lane four," the guy says. So I go to lane four. When I said all Detroit iron I meant it. Wherever I look, all big old muscle cars with gigantic slicks and all the trimmings. Most driven by dudes that seem time-lifted right from the mid-60s.

Now for the burnout. I've never done a burnout with Hoosier drag radials that are really slicks with two very shallow straught lines around the circumference to somehow make them DOT-legal. Jim had told me to do the burnout in second gear. I saw videos of Palmerblock producing fierce smoke with these same Hoosiers. So I drive through the nearly dry gulley, pull the e-brake tight, and... then courage deserts me and I am just convinced I'll fry my clutch if I do it in second. So I chicken out and do it in first. Well, the car isn't happy. It's wheel hop city and the Hooisers drag the car forward even with the e-brake locked to the max.

And I'm racing a mean looking nuscle car Challenger--no clapped-out Civics here. Now what RPM should I launch at? 3000, 5000, 7000? I decide to go for around five. Well, the Challenger blasts off with a 1.69 60-foot and disappears into the distance, doing an 11.9. I, on the other hand, look like an idiot. 5000 rpm is way too much and the Hoosiers spin and the car bucks. Okay, off the gas a bit and into second. Ahemm.... that WOULD be second if I still had my B&M shortshifter, the one that bent my shifter cables so that I returned to the stock box with its l-o-n-g throw. So second won't go in. I eventually cross the finish line with something good enough to beat a stock SRT-4, but no better. Back to the pits and waiting for the second of just two time trials.

I watch the action and realize that the NHRA might be closer to the NRA than to your typical import fest. Every stinking car hits 10s and 11s, and some do 8s. A Diesel truck does an 11.1. I might well be the slowest car at the entire event. I mean, almost everyone here would show Oside JimC's awesome maximum-boost, nitrous-ed, beslicked RSX speed demon the taillights.

Second time trial. This time I get paired with, thank God, "only" a stock-looking 05 Mustang GT. I do another painful, whimpy first-gear grind-out that probably made Mr. Hoosier spin in his grave, and once again hop off the line in a most-embarrassing way. I am not exactly sure WHAT the Hoosiers are doing as it all happens much too quickly, but second again won't go in and my gears grind. I think, "Shit! I DID win two trophy events this season and came in second twice, so I think I do know how to drive." Well, the Mustang gets a jump, but then for some reason slows down and I "win" the time trial. The good news: a trap speed of 108.03 mph, my best ever. The bad news: my ET stinks. And I mean as in horribly, awfully embarrassing. Some of the muscle dudes run low12s and high 11s with that sort of trap.

So then my beloved unexpectedly shows up and parks herself ringside. Just as I am getting ready for my first-ever NHRA Sportsman point run. I have no idea what to dial as both my time trials stank up the place with wheelhop and shifting problems. I decide on a 13.5. That's better than the 13.7 and 13.8s I can get with my street tires, so I figure it's safe as I apparently still have no clue how to use the Hoosiers.

The big guns go first and it's not only their speed that's demoralizing, but also their incredible consistency. Dial 10.72. Actual: 10.725. Dial 11.33. Actual 11.332. And so on. Car after car. Sure. No biggie with automatics, but still.

Then my time comes. I draw an innocuous looking littel trucklet, but there's obviously more to it as he dialed a 12.69. So with me beloved looking on, I do my best to put up a credible show. I am still using first for the burn-out, but actually managed a whisp of smoke and entertain the crowd andf the wife with some of the trademark metallic whine of the Comptech blower that actualy hit 10 psi (no datalogs as they wouldn't let me) during the runs.

So we stage... and I swear the stupid track all of a sudden isn't quite level anymore as the car seems to inch ahead on its own. WTF? Orange lights start counting and the car creeps just enough to.... redlight. Auuuuuugh!!!!! So I take off anyway, silently cursing myself, the people who built this miserable, slanted track, and everyone in the clutch business. This time the Hoosiers bite, the car hops less, second goes in after a bit of coercion, but, of course, I lose. Would have lost anyway as the trucklet ran a 12.728 on his 12.69 whereas I have, by far, a personal best. 13.167 at 107 mph, thus running way under. Okay, so that's good news/bad news. Lost in the first round in front of my honey, but ran a personal best.

But Sac Raceway isn't done yet. My last redlight came two cars before the Christmas tree conked out and it had redlighted me when I could have sworn I was well on the safe side. This time the slip shows neither reaction time nor 60-foot. Or my T4. So I take my 13.167 with a grain of salt. I also realize that even with the Mugen SS, my stock mounts can't handle the motor. So before I take the car to the track again I'll instal stiffer mounts. The "creeping" clutch needs adjusting. And I need another shortshifter so the gears go in.

As for NHRA points racing, I am not sure I like the idea of being the sole modified import among several hundred growling, snarling monsters whose idea of an off-day is being 0.05 over a 10 second dial.

Posted by conradb212 at 2:07 PM

December 2, 2005

ECU tuning enters console racing

I am an avid fan of console racing games. I've loved and played every release of Gran Turismo for years, as well as virtually every other racing game ever made. I prefer realism over arcade-style action, and I'm in awe of what the game developers have been able to do. In Gran Turismo 4 I can take hi-res pictures of my favorite cars that look so real that they fool most casual onlookers. Some other games let me modify and tune my cars with real brand name components, and when I am done I can even get on the dyno to check the results.

Now Swedish game developer SimBin Development Team AB is taking the genre to the next level by licensing real life racing technology from Australian MoTeC, perhaps the leading developer of specialized aftermarket ECUs. SimBin states, "SimBin and MoTeC will together integrate more of real racing telemetry functions into the next generation consoles. The general idea is to let people swap and exchange files on their consoles, where all data can be compared and recreated in the game, and that people will use this to analyse their driving techniques and help their friends improve by swapping these files."

Where will it all lead? Will games of the future allow you to plug in your favorite third party ECU and then use its actual software to tune your on-screen vehicle which will then react and behave like the real thing? Will racing teams use advanced gaming simulation to test settings of actual race cars? And, more commercially, will auto manufacturers more and more look towards near perfect simulations to actaully let prospective customers try out and test-drive cars? The latter is not too far-fetched: When I bought my Acura RSX Type-S, I not only had fallen in love with the car because I had driven it in the Project Gotham 2 video game, I also flummoxed the sales man when I told him I did not need a test drive because I had already driven the car in a game and knew how it sounded and how it handled. I was right.

Posted by conradb212 at 2:06 PM

November 29, 2005

A supercharged year

Well, time flies. It's been over a year since, after a long wait, Comptech Sports USA of El Dorado Hills, Calif., installed their supercharger system in my 2004 Acura RSX Type-S. Mine was the first customer installation and so I learned all about being a "test driver," recording every knock and every other little thing via the Hondata K-Pro programmable ECU, discussing it with Comptech and Hondata so that the final product would be as close to perfect as it could be.

Despite all the effort that went into designing and testing the supercharger kit, problems developed. This was to be expected, but it still came as a bit of a shock when first the so nicely designed tensioner and then the blower snout showed weaknesses that needed engineering corrections. This showed me that even extensive testing does not also reveal all inherent problems as neither the tensioner nor the snout (nor anything else) failed in my test car.

I also learned a lot about fuel injectors. Over the past year I must have tested almost half a dozen different injectors in my car, and they each perform a bit differently and require different calibration. They even have an impact on gas mileage. I still liked my (expensive) Power Enterprise injectors best, but it is plain amazing how well the modified Honda injectors Comptech ships with the Stage 2 kit work. I have had those in my car for many months now, and even with the 3.3-inch pulley they are not nearly maxed out.

I am disappointed in two things. First that we never managed to find the true source of a weird MAP buffeting at high RPMs. It can clearly be felt, and it shows up big on datalogs: boost fluctuations of up to a psi with an irregular frequency of between one and seven or eight times a second. I am certain the car would run better without it, and I simply hate an irregular, unexplained phenomenon. I even sent Magnuson a well documented inquiry. I got a "due to the high number of tech assistance request it will take us a few days...." and nothing more.

The second is the aftercooler. Though we have an exceptionally well built motor, reading Corky Bell's "Supercharged!" convinced me that charge cooling is really needed/beneficial at anything more than street level boosting. I am a realist and know that no matter how well run and professional it is, a relatively small tuner company like Comptech has too many irons in the fire to crank out whatever products we want. What frustrates me a bit is that the cooler was supposed to be available many times within weeks over the past 13 months, and it still isn't. I personally feel that had I been set up to at least test and tune the cooler, it would have been to Comptech's advantage.

I probably should also mention the realization that power is one thing and traction another. A dedicated drag racer colleague pretty documented in his supercharged Acura RSX what's needed to actually get the power on the road, so if quartermile numbers are part of what one expects from a SC kit, then the kit itself is only half of the package. Drag radials and then slicks are the other half. My own switch from Kumho Excta 712 street tires to stickier Falken Azenis RT615 helped a bit, but did definitely not solve the traction problem. I am about to order a set of Hoosier drag radials specifically for the track.

Overall, though, it's been a terrific, exciting experience and I certainly learned a lot.

Posted by conradb212 at 2:06 PM

October 18, 2005

"Closed loop" tuning for full throttle?

While I generally specialize on Hondata's K-Pro platform for Honda/Acura's K-Series engines, I also follow other ECU tuning platforms. My turbo-charged Chrysler PT Cruiser PT, for example, benefits from some very economical Mopar performance solutions. In addition, there are ECU piggyback systems, like the PPQ from Psi-Fi Motorsports.

In the www.ptcrew.com Cuiser enthusiast website, I cam across a very interesting article on PPQ tuning. ModMike there mentioned closed loop tuning. In essence, he promotes using the add-on computer to keep the car running in closed loop all the time.

For those less familiar with ECU/PCM tuning concepts, here are the basics: modern automotive computers essentially have two modes of operation, "closed loop," and "open loop."

"Closed loop" where the computer takes control and aims for what it considers optimal running conditions. Closed loop is general used during cruising where the computer tries to maintain the stoichiometrially ideal air-fuel ratio of 14.7 part sof air to one part of fuel. That theoretically allows for complete combustion of all gasoline and thus cleanest running.

In "Open loop" the computer abandons its "big brother" approach and instead reads fuel values from fuel tables. In general, open loop kicks in when you exceed a certain degree of vacuum in the intake, i.e. under medium to full throttle. There are other conditions where the computer switches into open loop, like when the engine is cold. Some ECUs have three or four open loop modes,

My view of the situation was always that in a programmable ECU, all you have to worry about in closed loop operation is that your short term fuel trim isn't too big. Short term fuel trim is basically the difference between the fuel tables, and what the computer has to actually allocate in order to stay at 14.7:1. As long as the computer does the work, why should we worry about short term trim? Because short term trim often affects long term trim, which means the computer "learns" to always allocate more or less fuel so that the short term corrections in closed loop are as close to zero as possible. A side note here: If one can edit fuel tables within the table areas generally used during closed loop operation, always aim for being a bit richer than necessary. That way, when an oxygen sensor fails, you're still safe because you're running richer instead of leaner.

In general, the ECU tuner's task is to extract the most from open loop operation by optimizing fuel, ignition and , if available, cam angles, under full throttle. In an NA motor, you generally want perhaps a 13.2 to 1 AF in open loop under full throttle. With forced induction, you'll be aiming for 11.5 to 12. With ignition, you aim for highest possible advance without detonation (that is a whole other project, one that depends on the specific knock sensor algorithms in a platform).

The problem often is that the ECU isn't entirely in open loop and still butts in. So if you managed to have a nice, consistent 12.0 AF in third, you may find that it's nowhere near as perfect in fourth or fifth gear. Then there's temperature compensation. Some ECUs do a good job at compensation for intake air temperature, others do not.

Truth be told, I had always thought the ideal tune would consist of running entirely in open loop. That way you'd have the computer out of the way, and the car would run optimally due to masterfully optimized fuel and ignition tables. I simply had never thought of doing it the other way around, of keep the car in closed loop all the way, so that you simply tell the ECU what AF you want under every load/rpm condition. It almost sounds too good to be true.

Unfortunately, I don't know enough about the PT Cruiser ECU/PCM to form a conceptual tuning strategy in my mind. I believe the PT uses what essentially amounts to a knock sensor-based ignition map overlay that probably starts with a base map, and then is modified via short term and long term knock sensor input. I don't know if it is possible to edit that map, or the ignition map, with the PPQ software (I also know that it doesn't work right in my car).

So... plenty of questions and issues, an interesting concept (closed loop running under WOT), and a desire to figure it all out.

Posted by conradb212 at 2:04 PM

September 29, 2005

What makes a 330 hp smog-legal Acura RSX?

Every now and then I marvel at the fact that my rather stock-looking Acura RSX Type-S has a 330 hp engine under its hood, can do 0-60 miles per hour in 4.8 seconds and run the 1/4-mile in the mid 13s. What did it take to do all that?

Truth be told, I spent a lot more on the car that I needed to get all this power. A completely stock RSX with a suitably configured Comptech supercharger can get very close to the crank horsepower of my car. But that is not how I got started. Like most other modders, I added piece after piece, month after month, and each made me feel good.

First I got a set of nice 17-inch Kazera wheels from tirerack.com, with Kumho 712 tires. Then I installed a Comptech Icebox intake and a Comptech street header. Then a Fujitsubo PowerGetter exhaust. Then the Hondata ECU flash. For handling I put in the Mugen Sport Suspension. Then I upgraded the ECU to the incomparable Hondata K-Pro. The Hondata Intake Manifold Gasket went in. A tuning session led to switching to an AEM Cold Air intake. A B&M short shifter went in. For cosmetics I got a JDM-style wing, had the headlights blacked out, and redded the taillights. Then came the Comptech supercharger for which I played guinea pig for Comptech. In the process, they also installed their titanium front strut brace and rear sway and tie bar. Now that the supercharger was in, I got an Autometer boost gauge, and ACT performance clutch and heavy-duty pressure plate and a Comptech lightened flywheel. While the transmission was off, we also installed a Quaife limited slip differential.

Has it been fun? Absolutely. Tons of it. Would I do it again? Yes. Sure, for the extra money I spent I could easily have bought a car that already had that sort of performance, but that's no fun.

Posted by conradb212 at 2:04 PM

September 22, 2005

Live ECU tuning at the track, and a trophy

Last night I got my first drag racing trophy. It wasn't much of a trophy, just sort of a big mug with the Sacramento Raceway logo and graphic. And I was only runner-up, losing the final bracket race by 8/1000th of a second to a much slower but extremely consistent automatic. But it felt sooo good to get that silly trophy.

This was one of the last Wednesday drags of the season, so about 250 cars showed up. We only got two time trials, which was bad news for me as I had just installed a new pulley on my supercharger and needed to adjust the Hondata K-Pro calibration for it. I had done some street tuning, but the track is different. I always datalog all of my runs.

On my first attempt I did a 13.9 at 104mph, but my air-fuel ratio went into the low 13s above 7700 rpm. Boost was lower than expected, mostly in the high 7s with an occasional rise into the 8s. Anyone who has seen a Comptech boost curve knows that it is difficult to read because of some internal buffeting that makes the MAP sensor show peaks and valleys with amplitudes of up to 0.8 psi. I also noticed fairly substantial knock. None in second, 6 at high rpm in third, and another 12 all through 4th. Not good. I wasn't going to remap my entire ignition tables sitting in a line of cars, not knowing when my next time trial run would be, so I decided to try ignition compensation by gear. I quickly glanced at the K-Manager documentation: "To retard the ignition, enter a negative value." Retard... Retard.. okay, so that probably means a lower number, which I needed. So I entered -1 for third, and -2 for fourth and fifth. I also adjusted fuel, wondering if I was making a mess of things doing it all on the fly, and also what temperature compensation had already done with my starting line IATs in the mid-120s.

Anyway, I really blew my second run when I couldn't get it into 2nd, but the rest of the way it was fine. Datalog showed that total knocks were down substantially, and that gear ignition compensation had actually worked.

Then we got into tropy runs which I both love and hate. I am still on a quest for lower ETs, but since I also want to win, I usually get off the gas when an opponent is obviously beaten. First trophy run: 13.9 coasting through the finish line since my opponent, a nice E36 M3, had apparently misjudged his dial-in. Second trophy run: a twin turbo 280ZX who had a reaction time of 0.001, then ran under by almost half a second. I had an average run, but beat him because he ran under. Third run against a Prelude who also couldn't even come close to his dial-in, so I got off the gas early and did another 13.9 as I coasted through the line at 90mph. Semi-final against an Acura who had beaten me before. He ran a near-perfect run, but I beat him with a 13.8 on a 0.08 reaction time and went off the gas early. The runs now had no more knock and AF in the high 11s. Boost, however, was only in the mid to high 7s and actually decreasing a bit after 8000 rpm. Could it be that my belt was slipping a bit with Ryan at Comptech torqueing it the way he thinks is right as opposed to what the instructions say?

For the final run I lowered my dial-in to 13.7 because it was cooler now, in the 90s, and I did not want to break out. I got to race the dreaded middle-aged lady from Folsom who drove that 18.0 second Kia and generally ran 18.05s like clockwork with near-perfect reaction times. Needless to say, she didn't have wheelspin problems. The 4.3 second headstart was a bitch, I spun the wheels (as I did on every launch yesterday, despite the Falken 615s), caught her at the finishing line, inches too late. 13.8, 105 mph trap.

Fun evening all in all. Tuning the car majorly while waiting to stage is a handful. The knocks, AF problems, lower-than-expected boost and sky-high IATs kept me busy. My inability to find the proper launch infuriating as it probably added half a second to each run. The only other RSX there, I/H/E/Hondata with a good driver, did 14.6-14.8. The winner in the other import class was a S2000 who did 14.2s and beat a E46 M3 (the new one) who did 13.9s in the finals. Maybe Sac Raceway just isn't a very fast track.

So now it's back to the drawing board. My 3.3 inch pulley only does mid 7s to low 8s in boost. My launches bite; still in the 2.3s 60 foot. The calibration needs some real work; no way can the official Comptech Stage 2 calibration be used for the 3.3-inch pulley without drastic changes.

Posted by conradb212 at 2:03 PM

September 19, 2005

It's amazing that third party performance kits work at all

In general, superchargers are lauded for their simplicity and reliability. The blower itself is guaranteed for 100,000 miles and doesn't need any maintenance at all. Combine that with a company famous for its engineering, experience, and customer support, such as Comptech USA in El Dorado Hills, Calif., and you have an unbeatable combination. Well, yes and no. It really depends on your expectations. When you consider that it costs automobile manufacturer billions to design a new platform and millions to create even small parts, and that it then takes millions of test miles and a couple of years of actual production to work out all (or most) of the bugs, it's amazing that performance kits, like superchargers, work at all. I mean, the design budget is minuscule, and often only a few dozen of an item are sold. Yet, customers have very high expectations and are quick to diss a company or product if it doesn't perform flawlessly.

This morning I witnessed an example of the struggle relatively small tuning companies go through. I stopped by Comptech to have them replace my 3.6-inch blower pulley with a 3.3-inch one in order to increase boost from 6 to 8.5 psi. One of Comptech's experienced mechanics did the work. He found a couple of parts that showed wear and replaced them. Once everything was back together he started the car to see if everything worked as it should. It seemed that way until he pulled the throttle cable a bit to see if the belt was nice and tight under load and changing rpm. Well, as he let go of the throttle and the engine rapidly dropped revs, the belt sort of slackened on top of the power steering pulley for a split second. It looked like it hopped just a bit. Needless to say, you don't want that. The belt might come off.

A Comptech design engineer stopped by and the matter was discussed. Did part of the tensioner catch somewhere and not flex back properly? Did the tensioner move too much? Everything came apart again, and the engineer installed a small metal insert to stabilize the long bolt. The mechanic cautioned that the thread of the bolt might catch in the bolt. The assembly went back in, but the belt still did that little hop when the throttle was released. Was the belt too loose? It was tightened until it bottomed out. The hop was still there. So the tensioner assembly came off again and was taken apart. The engineer took the two springs and tested them on some machine. Aha! They did not have the proper tension. New springs were installed and the tensioner went back in. The hop was still there, which meant that the tension of the springs was momentarily overcome. The assembly was tightened beyond spec and that fixed the problem, but that did not seem an acceptable solution to the Comptech engineer. He came back with two small springs that fit inside the larger springs. They had to be cut to fit properly. Ryan, the mechanic, wasn't too happy as he still felt the steel insert would make the threaded bolt catch. Steve, the engineer, felt otherwise. So the tensioner assembly was fitted with the dual springs, and then tightened (there was discussion as to how much to tighten; the mechanic felt it should be less than what was in the instructions). Anyway, with the new double springs, the hop was gone. No one seemed completely happy as there was agreement that the threaded bolt MIGHT catch on the steel insert, and that might either eat away the insert or dig into the bolt. Nothing terrible would happen, but it just wasn't a totally satisfying solution.

Now multiply that experience with all the things that can possibly go wrong, or not quite right, in an aftermarket supercharger system with all its brackets, fittings, nuts, bolts, belts and whatever else, and consider that the kit then gets installed into cars with very different modifications, often by people who are not professional mechanics, and it's a miracle these kits work as well as they do. The lesson really is that we should never expect perfection and flawless operation. Those who can't stomach that possibility should probably remain stock.

Posted by conradb212 at 2:02 PM

September 6, 2005

Back at the track with new tune and Falken RT-615 tires

Comptech had my Acura RSX for a couple of days so they could dynotune the Stage 2 supercharger Hondata K-Manager calibration for their modified Honda injectors. After I got the car back, there was a nasty noise on acceleration, and the tune didn't look too good. I brought the car back, feeling quite uneasy about the noise. Then again, the worst-case scenario was something wrong with the motor, and that would have given me an excuse to go for forged pistons and stronger rods. Fortunately, the problem was minor: the power steering line was touching the tie-rod, and that caused noisy vibrations. Billy at Comptech had managed to retune the fueling nicely and the car ran well, clocking in at 257.5 whp on Comptech's DynoDynamics chassis dynamometer.

In the meantime, my Falken RT-615s had arrived at Big-O Tires in Cameron Park. I had high hopes for them as their rubber compound is much stickier than the Kumho Exsta 712 tires I had before.

I went back to Sacramento Raceway to test that theory. Once again it was very hot, over 100 degrees. Though I got smoked by a turbocharged Civic in my first time trial, it was immediately obvious that the Falken tires provided much better grip. As before, I datalogged the 1/4-mile runs on my notebook. Whereas before I could hardly apply 30-40% throttle in first, now I could apply 80 and even 100%. I finally broke into the 13s and ran farly consistent 13.9s all night long. That is still pretty slow given my trap speed of over 103mph, so I will have to work on my launch technique. It was a fun evening and I made it all the way into the final trophy run in my class. I lost that when I spun the tires on the worse of the two lanes.

After a few trips to the drag strip, it's obvious that getting good times is a lot more difficult that many people think. And a drag strip is not this perfect, grippy, smooth piece of asphalt; it's an ever-changing patchwork where you never know if you'll get traction or not. Still, it's tons of fun, especially with being able to datalog all runs for post-race analysis.

Posted by conradb212 at 2:02 PM

August 26, 2005

Anatomy of a drag race: PT Cruiser vs Hemi Charger

One of the great things about drag racing is that it gives you a safe venue to get the speed bug out of your system. Another is that it lets you know how fast your car really is, which means the temptation to constantly prove it at the stoplight is lessened considerably. But perhaps the nicest thing about drag racing is that it is so much fun.

For those who've never raced, hobby drag racing is simple. If you're lucky enough to have a local dragstrip, head on over. There are often weekday events for regular guys (and girls) with regular cars. At Sacramento Raceway it costs just $15 to race on Wednesdays. What happens is that you get to do a few time trials. Then you "dial in" a time and it is marked on your windshield and side window. The dial in time is fast a bit faster than you think you can go, and it is used for "bracket racing" competition. Bracket racing uses handicaps. So if you dial a 14.8 and your opponent dials a 13.7, you get a 1.1 second headstart. However, it's only 1.1 seconds if both of you have the same rection time. If your opponent sleeps at the wheel and has a 0.7 reaction time and you have a 0.2, you just added half a second to your headstart. All this as a prelude to what was one of my most satisfying races ever.

I had lost in the first round of eliminations to a truck, crossing the finish line 2/100th of a second too late. So I was headed to the "loser lanes" 1 and 2 where eliminated cars could continue racing, without handicap, but still with reaction time included.

As luck would have it, my 2004 PT Cruiser GT was paired with a 2006 Dodge Hemi Charger. An all-Chrysler race. A Mopar race. A race between what is sold as the muscle car successor to all the great muscle car Dodge Chargers of the past and Chrysler's small retro paddywagon. A race between the almighty Hemi V8 and turbocharged 4-cylinder. As I drove up to the staging lane I felt history weighing on my shoulders. The Hemi Charger did some burnouts. I gunned the PT's turbo engine to treat the crowd to some blow-off valve hisses. I knew everyone considered it a mismatch. PTs aren't fast. Hemi Chargers are. Then again, the 2006 Charger is a big 4-door beast that's based on the Chrysler 300 platform. But it has a Hemi.

So my heart was pounding as I staged. Then the lights counted down and we were off. I'll include the numbers from the timeslip in what happened next. Makes it more dramatic. I caught a very good light, with a 0.176 second reaction time. The big Hemi Charger was no slouch either. He got off the blocks in 0.317, which means he was 141 thousandths of a second behind me. Though the Hemi Charger has an autostick and my PT a 5-speed, we did almost identical 60 foot times. I had a 2.268, the Hemi a 2.274. We passed the second timer with virtually identical times: I had a 6.317, the Hemi a 6.318. I power shifted from 2nd to 3rd, which means I never lifted my foor off the gas. The Stage 1 computer in my PT does a "soft rev limit" and so I can do that.

Despite the powershift, the Hemi now inched closer. I passed the third timer after 9.605 seconds, he did it in 9.576 seconds. So now he was just 112 thousandths behind me. At that point my speed was 75.884 mph, his 75.657. I powershifted from 3rd to 4th and felt the PT's engine straining harder as the big and not very aerodynamic body encountered ever more wind resistance. I passed the fourth timer at 12.438. The Hemi in 12.391. I was now just 94 thousandths ahead. The big Hemi inched closer yet, and we passed the final light, the end of the quarter mile. Who'd pass the finish line first?

I did. With a 14.878 to the Hemi Charger's 14.788. I won by 51 thousandths of a second.

The Hemi Charger did not return to race again. It must have been embarrassing to lose to a PT Cruiser. He ran a very good race. We both did. The small difference in reaction time meant I won. And it felt really, really good.

Posted by conradb212 at 2:05 PM

August 23, 2005

Car back at Comptech for injector tuning

Yesterday I brought my RSX back to Comptech in Eldorado Hills. I had been running a set of standard (read: inexpensive to buy) Honda injectors that Comptech had modified to flow about 530cc instead of the stock 240cc or so. Comptech is using those as a reliable, inexpensive alternative to expensive third party injectors for their Stage II supercharger upgrade kit. Another advantage of using Honda injectors is that they fit without having to splice wires. Anyway, Comptech had some customers experience Check Engine lights with these injectors and so we wanted to see why. Turns out that the modified injectors had a different fuel delivery curve than stock injectors. Under light load they delivered too little and under full load too much. That's no big deal as in closed loop, the ECU will compensate via short term fuel trim. However, it may be enough to trigger a Check Engine light for a "lean condition" that customers without programmable ECUs or scan tools cannot diagnose or eliminate.

So Comptech is now doing a new baseline for my car on their Dyno Dynamics chassis dynamometer, and will then re-tune the car so that the fuel curves are okay. I will then road-test the new configuration and check it via K-Pro datalogs.

I also plan on replacing my current 3.6-inch pulley with a 3.3-inch pulley later this week. That should increase boost from 6 psi to maybe 8 psi. Comptech also has a 3.1-inch pulley for the new MP62 snout assembly, but I'll switch to that once the aftercooler is installed, to make up for the cooling-induced lowered boost. As for the aftercooler, it is still not finished. The two test cooling cores are still sitting on a bench, without all the other parts required to install them in my car for testing.

After experiencing a total lack of traction at the drag strip last week with my Kumho Excta 712s I am switching to Falken RT-615s which have a much stickier rubber compound. Should be interesting to see how much of a difference it makes. The Kumhos are not bad tires, especially for the money, but they simply do not provide good traction in powerful frontwheel drive vehicles.

Posted by conradb212 at 2:01 PM

August 18, 2005

At the track

Yesterday I took my supercharged RSX to Sacramento Raceway. I had never raced it before and was wondering how it'd do. Based on experience on the street I expected to have plenty of power, but not enough traction. And that is exactly how it turned out. Needless to say, I took my notebook with me so I could datalog and study my runs on the K-Pro's K-Manager software.

On my first run I basically just sat there at the starting line, spinning my wheels. I had launched at perhaps 5000 rpm and it was like the wheels were spinning in butter. I must have just stood still for a good two or three seconds. I still managed a trap speed of over 103 miles per hour, but the time was miserable, high 14s. I analyzed the datalog, found that at least my air-fuel ratio was perfect and that the engine had no knocks at all, and that even my intake air temperature wasn't too bad. I also found that the IAT can drop by as much as 20 degrees Fahrenheit over a single 1/4-mile pass.

I did six runs in total, each with a different launch technique. Nothing worked as my 225/45-17 Kumho Excsta 712 tires were simply overmatched by the 260 wheel horsepower of the rather light car. My trap speed was consistently in the mid 103s, but I never managed better than a 14.1 through the quarter. In general, a trap speed of almost 104 mph should be good enough for mid 13 runs.

Before my last run I all of a sudden had a Check Engine light. Normally that would be cause for serious concern. However, with the notebook attached to the ECU I could quickly determine that the error code was for a lean condition that did not worry me. I am running experimental fuel injectors that are lean in closed loop where the ECU corrects via short term fuel trim, but run rich enough in open loop. Thanks to the Hondata K-Pro, I could diagnose that MIL on the fly and erase it as I was driving up to the starting line.

This morning I ordered a set of Falken 615RT tires. They are far stickier than the Kumhos and should make a difference. I could have simply gotten a set of true drag radials on stock wheels, but I don't like changing wheels and I do like traction on the street as well, so the Falkens may be a good compromise.

Posted by conradb212 at 2:01 PM

August 9, 2005

IPS-Ksc -- too good to be true?

After all the cam horror stories (or at least the "well, it'll always be a compromise" stories) about cams, the news so far on the Intrinsic Performance IPS-Ksc cams sounds almost too good to be true: great drivability, plenty of power, idle, quiet operation, apparent promise of acceptable emissions, decent gas mileage. Where's the hitch, the weak spot, the compromise? There's got to be one if the no-free-lunch theory holds.

And yet, consider the reports by the initial IPS-Ksc "test pilot," OsideJimC:

"First was a little run around the neighborhood, felt goooood. Lots of torque, nice throttle response. Then a short sprint on a nearby highway, WOW, the car responds like never before. Massive torque, instant throttle response, OK, this is FUN."

"OK, drove about 90 miles today out in Temecula wine country. About 40 on the freeway, 10 in the city, the rest out in the country. Wow I love my car. All my earlier impressions remain intact. Great throttle response, outstanding part throttle driveability. inital fuel economy impressions are favorable, drove all day on 1/8 tank (indicated), but as stated before real mileage numbers will come when I go back to a 9psi / 91 octane setup. A good example is at one time I as behind a truck going up a steep hill at 45 (5th gear), got a chance to go by, just moderate throttle and next thing I know I'm doing almost 90, no downshift to 4th, try that N/A!!"

"OK, it's Tuesday. Not much new to report. Still love 'em!! I did run through a talk of gas. Got 23mpg, not bad for a 343whp car! But going back to 9psi will yield more realistic results since that's my "normal" setup."

"The only issue I found was in heavy traffic yesterday, going 30 in 2nd I switched from a slow lane of traffic to a faster moving one. Changed lanes and punched the throttle, tire smoke filled the passenger compartment, oops. Reminder to self, no need to hammer the throttle to get results."

Posted by conradb212 at 2:00 PM

August 8, 2005

The Hondata k100--9 months later

Almost nine months after its November 19, 2004 introduction, Hondata's k100 remains perhaps the least understood and most perplexing of the company's Honda ECU upgrade products. Intended to offer a less intimidating, less expensive non-userprogrammable version of the Hondata K-Pro, the k100 really never established a niche and perhaps there really wasn't a need for it.

Let's revisit what the k100 is, what it can, and what it cannot do. The idea behind the k100 is to provide the exact same ECU programming capabilities as the K-Pro has, with the sole difference that only a dealer can actually make programming changes. In order to facilitate that, a stock Honda ECU is prepared in the exact same way as an ECU that is being upgraded to K-Pro. However, the k100 daughterboard is much simpler than the K-Pro daughterboard and does not have its own programming interface. The ECU that's being upgraded to k100 status also does not receive a USB connector cutout in its metal housing.

How is the k100 programmed then? The procedure is not complicated but rather cumbersome. The dealer must remove the customer's k100 ECU from the customer's car, open the ECU, remove the motherboard and install the motherboard in a "true" K-Pro ECU that has the USB cutout. He then removes the k100 board and replaces it with his K-Pro board. This "Franken" ECU then goes back into the customer car for tuning. Once tuning is finished, the dealer then removes the ECU from the customer car, replaces the K-Pro board with the customer's k100 board, puts them back in the customer's ECU casing, and then puts the now reprogrammed k100 back into the customer's car. Quite an ordeal.

The theoretical benefits to the customer are that s/he never needs to worry about tuning. The dealer does that. The beenfit to the dealer is that he has a captive customer who needs to come back for re-tuning or software updates. Manufacturers of power adders may decide to bundle their products with a specially tuned k100. To the best of my knowledge, only Comptech has done that so far, with its street supercharger kit for the 2002/2004 Acura RSX Type-S.

There are problems. Judging by the number of questions asked in forums, customers seem very confused about what the k100 actually is. Dealers have been reluctant to accept the k100 because Hondata requires them to do the board upgrades themselves, which requires training at Hondata. The soldering involved is not trivial and the procedure is somewhat complex. Once a k100 has been programmed, it cannot simply be tweaked if it doesn't work right in a customer's car. This means that k100 calibrations must be quite conservative. Even then, a customer's modifications may not agree with it. Further, Hondata releases frequent software updates that often include bug fixes and important enhancements. They can easily be loaded into the K-Pro. Loading them into a k100 requires a trip to the dealer (theoretically, a dealer need not be involved to program a k100; a K-Pro owner willing to perform the above described procedure can do it). Customers have also been irked by the fact that pricing for a k100 to K-Pro upgrade has been left up to dealers. It's a simple procedure (making the USB cutout and replacing the k100 with a K-Pro board) but there are less than a dozen listed Hondata dealers worldwide that handle the k100.

There has been one big success for the k100. Since it is a non-programmable system, Comptech has been able to receive CARB approval for k100-equipped supercharger kits. Those kits perform much better than competing kits without Hondata functionality. I also hear that foreign Hondata dealers may be happy with the k100 as there is no need to send the entire ECU to the US.

All in all, one can sort of see the reason behind the k100, but Hondata really never made a clear and convincing case for it. It's hard to accept the idea of a programmable ECU that is rendered unprogrammable while having the same altered functionality compared to a stock ECU that makes programming/tweaking/tuning a virtual necessity. (Consider also that the K-Pro board is only the interface; the Honda ECU is inherently programmable, and it is the Hondata modifications to the motherboard, combined with the K-Manager software, that make the Honda ECU programmable).

At some point, well before the launch of the k100, there were ECU forum discussions about the business aspects of the K-Pro at clubrsx.com. A lot of interesting ideas were offered, including many that addressed issues that I believe the k100 seeks to address. Hondata did not, as I had hoped, participate in that discussion. In my opinion, that exchange of ideas and opinions could have led to interesting alternates to the current k100.

Posted by conradb212 at 1:59 PM

August 7, 2005

Intrinsic Performance FI cams - first result

Ron from Intrinsic Performance posted the first dyno results for their supercharger-specific cams on Oside JimC's Acura RSX Type-S equipped with an 11psi Comptech SC, Jackson Racing race header, 650cc injectors, Hondata K-Pro, Injen CAI and Comptech 2.5" exhaust. The dyno comparison was done at Church Automotive in Torrance, CA, on a DynaPack. Power went from 324 to 343 at the hub, and torque from 218 to 225 ft/lb. Most interestingly, the IPS cams almost completely eliminated the boost drop usually seen at the VTEC point. This means up to 3 psi more boost between VTEC and midrange, and additional boost even at high rpm.

These results seem to affirm Ron's earlier prediction: "As you may know already, overlap allows boost and fuel to blow right through and ignite a good portion of the mixture well out of the combustion chamber through the exhaust. This causes high EGT's. This is very bad. So, for a proper FI camshaft to perform well - overlap must be reduced or eliminately completely. This is what IPS-Kpsi's were designed and engineered to do. Moreover, the ideal FI cam profile will have significantly larger lobe area conducive to boosted application. And because there no longer exists an overlap condition, the pressurized intake charge will see less restriction at the valve due to the greater amount of valve lift realized with IPS-Kpsi cams. Lastly, the result from meticulously analyzing valve motion and harmonics, IPS-Kpsi cams allow Volumetric Efficiency to scale exponentially under boost, with superior valvetrain stability. We'll see torque curves and HP powerbands hold very strong past their peaks, unlike what is seen with stock camshafts. FI amplifies the engine's natural ability to make power." Ron further stated, "The benefit from overlap in an NA engine helps with cylinder filling at mid to high rpm. I think by the time you hit this portion of the powerband while SC'd, the blower will be doing what it does best. Therefore, I feel it will be an non-issue and that part-throttle driving (SC bypassed) will not incur any downsides other than the inherent parasitic losses seen with a SC installed." OsideJimC, the car's owner, reported, "I'm pleased to report no loss of driveability. Under light throttle the cams are very tame, no bogging and again partial throttle response is excellent. One thing my G/F mentioned, the car is quieter under light/medium throttle. Even WOT seems a little quieter, my theory is without the overlap less intake charge is burning in the exhaust, a very interesting by-product."

So this is a very interesting development. An earlier test with special Crower supercharger cams did not yield good results, and the general recommendation is to use the stock cams with supercharging unless the exact right cams are available. Looks like we now may have those.

Posted by conradb212 at 1:58 PM

August 6, 2005

Entering the world of blogging

Okay... so I installed the demo version of Movable Type on our main Linux server. The install went pretty smoothly, although I did have to look up a few things. For example, I wasn't sure whether I had the MySQL database running on the system or not. Turns out it was there, but the server wasn't running. Then the usual "Google to the Rescue!" in order to find how to start SQL, how to add users to SQL, how to give them proper privileges, and so on. Nothing is ever entirely trivial, but within an hour or so I had remotely installed Movable Type and configured it on the pencomputing.com Linux server.

What am I going to use it for? Initially just as a test to see how Movable Type works and how it can be used, accessed, customized and configured. After that I may figure out if I want dedicated blogs for some of the topics I am interested in, or perhaps none at all. Candidates for blog activity are my work with mobile technology and digital cameras, my work with automotive ECUs and superchargers, or perhaps some of my personal interests, though I doubt I'll pursue the latter.

Posted by conradb212 at 1:57 PM